Special Division

Fashion material

· Stout Series

PRODUCT

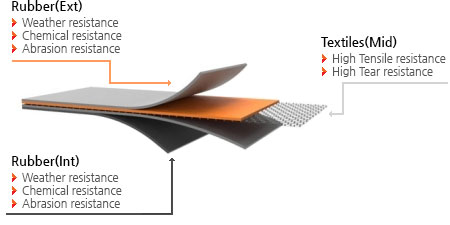

Rubber double coated on HT fabric. Stout series have high abrasion resistance, tensile and tear, which is Suitable for outdoor hypalon bags.

Base : rubber

Base fabric : TEXTILES

Thickness(mm) : 0.65 / 0.8 / 1.0

Tensile strength(Kg/5cm) : 180 ↑

more ▼

- Color and specification

| TEST ITEM |

Unit |

Direction |

SPEC |

Standard - Test |

| 0.65mm |

0.8mm |

1.0mm |

| GAUGE |

mm |

- |

0.65~0.75 |

0.75~0.9 |

0.9~1.1 |

KS K ISO 5084 |

| WEIGHT |

g/m2 |

- |

650↑ |

800↑ |

950↑ |

KS K 0514 |

| TENSILE |

Kg/5cm |

A |

180 |

180 |

180 |

KS K 0521 |

| B |

140 |

140 |

140 |

| ELONGATION |

% |

A |

20~50 |

20~50 |

20~50 |

KS K 0521 |

| B |

20~50 |

20~50 |

20~50 |

| TONGUE TEAR |

Kg |

A |

5↑ |

5↑ |

5↑ |

KS K 0536 |

| B |

5↑ |

5↑ |

5↑ |

· Super Series

PRODUCT

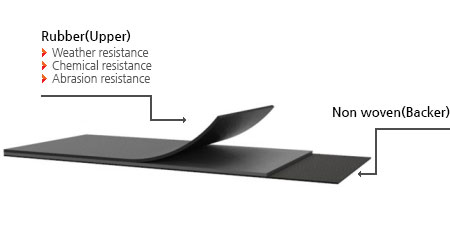

Super series have non-woven and high-abrasion rubber

composition without using any bonding material.

Various kinds of emboss are in high friction lever as well as easy

to design.

Base : rubber

Base fabric : Non woven

Patten : FP01,02,03,05,08,DE11,DIA

Thickness(mm) : 1.30

Weight(g/m2) : 800↑

more ▼

- Color and pattern

| TEST ITEM |

Unit |

Direction |

SPEC |

Standard - Test |

| GAUGE |

mm |

- |

1.30 |

KS K ISO 5084 |

| WEIGHT |

g/m2 |

- |

800↑ |

KS K 0514 |

| TENSILE |

Kg/5cm |

A |

50 |

KS K 0521 |

| B |

50 |

| ELONGATION |

% |

A |

40↑ |

KS K 0521 |

| B |

40↑ |

| TONGUE TEAR |

Kg |

A |

6↑ |

KS K 0536 |

| B |

6↑ |

· Gomme Skin Series-I

Base : Thin Rubber

Patten : FP01,02,03,08,DE11

Thickness(mm) : 0.4

Weight(g/m2) : 450↑

· Gomme Skin Series-II

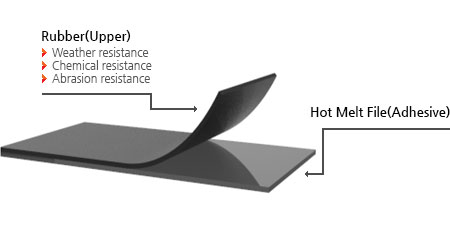

PRODUCT

1. Comsist of rubber onlt No-sew process is availavle by adding addiyional process on vacker. Patent registered.

2. Without using by any bonding and needlework, only with heat-press, these no-sew series fabrics are compressed in a moment.

So process time will be saved.

Base : rubber

Base fabric : Hot Melt Film

Patten : FP01,02,03,08,DE11

Thickness(mm) : 0.4

Weight(g/m2) : 450↑

GOMME SKIN Guide view ▼

more ▼

FINE® GOMME SKIN is a rubber sheet which can be bonded with other materials by Hot Press

▶ GOMME SKIN Composition

1. How to attach the GOMME SKIN to other material (Bottom layer)

- Case of application

- Color and pattern

| TEST ITEM |

Unit |

RESULT |

Standard - Test |

| GAUGE |

mm |

0.40 |

KS K ISO 5084 |

| WEIGHT |

g/m2 |

450 |

KS K 0514 |

| ABRASION |

Weight Loss, mg |

200 |

KS K 0818 |

| OZONE RESISTANCE |

Appearance |

NO CHANGE |

KS M 6518 |

| OIL RESISTANCE |

RATE OF TENSILE |

% |

5↓ |

KS M 6518 |

| RATE OF ELONGATION |

5↓ |

| RATE OF TEAR |

5↓ |

| OIL RESISTANCE |

RATE OF TENSILE |

% |

10↓ |

KS M 6518 |

| RATE OF ELONGATION |

3↓ |

| RATE OF TEAR |

3↓ |