Automation Machine Division

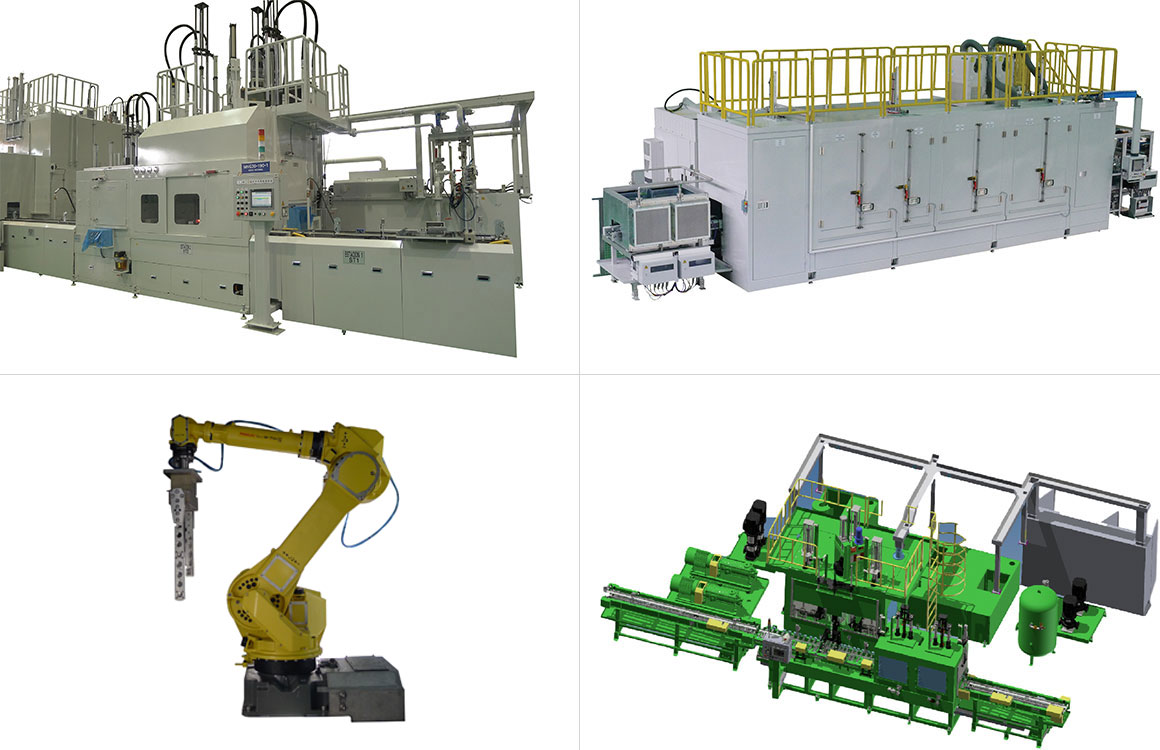

Washer

· Technical overview

The aim is to remove dust, oil, chips, and burr by spraying low and high pressure cleansing solutions according to the characteristics of the target object. The entire process leading to movement, cleaning, and drying are composed of an automatic process.

Since cleansing solutions are recycled after cleaning the target object, it can reduce the cost needed for cleansing, maintain clean working conditions, and reduce the number of management items.

· Classification of facilities

· Robot-type cleansing facilities

· Index-type cleansing facilities

· Lift & Carry-type cleansing facilities

· Combined cleansing facilities

· Conveyor-type cleansing facilities

· Gantry-type cleansing facilities

· Universal component cleansing facilities

· Cleansing type

· Low-pressure cleansing (1 ~ 35 bar)

· Mid-pressure cleansing (35 ~ 300 bar)

· High-pressure cleansing (300 ~ 500 bar)

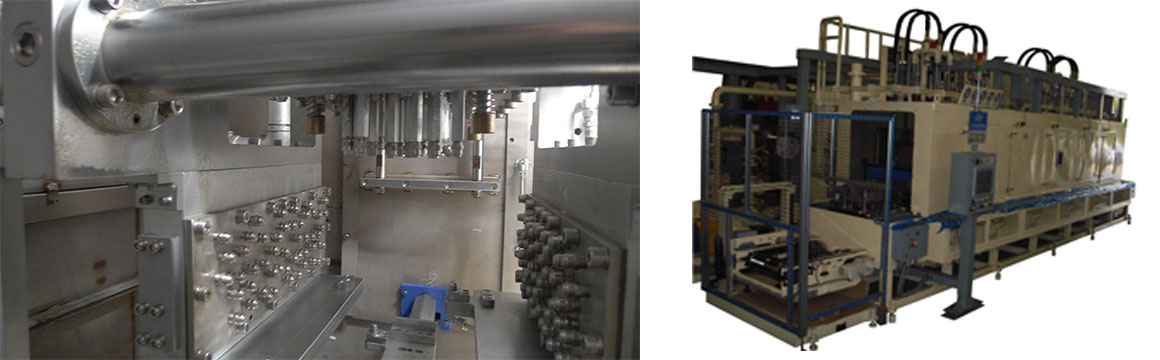

· Robot type / NC type / Lift & Carry type high-pressure cleansing facilities

By spraying high-pressure cleansing solutions at 100 bar ~ 500 bar, foreign substances and burr can be removed for securing highly clean conditions of the target object.

- Characteristic

· Can secure highly clean conditions

· Can remove burr

- Target product

· All products requiring cleansing

· Lift & Carry, index, and robot type underwater spraying cleansing facilities

Cleansing is carried out by immersing the target object in the cleansing solution. It can be used for cleansing the internal flow path by forming a whirlpool.

- Characteristic

· Excellent in removing foreign substances in the flow path

- Target product

· All products requiring cleansing

· Lift & Carry-type cleansing facilities

Used for precise cleansing by securing the accurate position while the target object is being moved.

- Characteristic

· Precise cleansing for target object

- Target product

· All products requiring cleansing

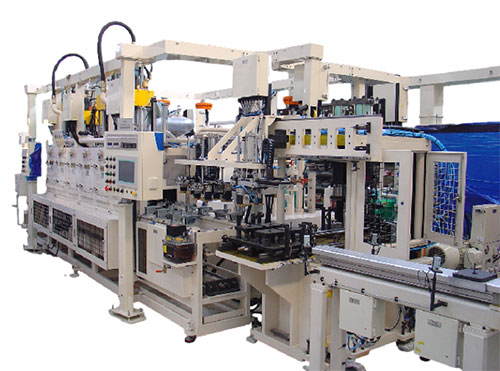

· Combined cleansing facilities

By adding the brush, press, and assembly process before and after the cleansing process, it can effectively lead to the reduction of individual investment costs and management for maintenance.

- Characteristic

· Reduction of investment costs for facilities

· Effective for maintenance

- Target product

· All products requiring cleansing

· Conveyor type cleansing facilities

Cleansing / Drying is possible while the target object is being moved on the conveyor. If necessary, cleansing / drying can be carried out more effectively by extending on the process for a certain period of time.

- Characteristic

· Wide-range use with inexpensive costs

· Short cycle

- Target product

· All products requiring cleansing

· Gantry in/out type cleansing facilities

Cleansing facility can be installed on the gantry loader return line for cleansing / drying in one process.

- Characteristic

· Can be installed in narrow spaces

· Inexpensive costs

· Inexpensive maintenance costs

- Target product

· Any product that needs cleaning

· Universal component cleansing facilities

Universal cleansing facility that can effectively cope with cleansing for different kinds of products.

- Characteristic

· Can be installed in narrow spaces

· Inexpensive costs

· Can cope with cleansing on different kinds

of products

· Low maintenance cost

- Target product

· All products requiring cleansing

· Major target object