Automation Machine Division

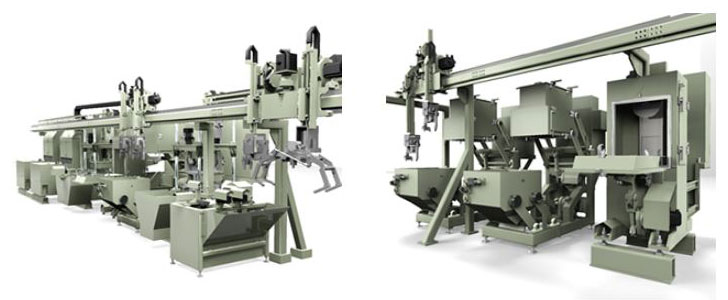

Post-casting processing equipment

· Technical overview

Automatic grinding line used for post-processing of the casting factory that removes molding sand remaining on the material and automatically removes burr and pouring gate after carrying out casting or die casting.

· Classification of facilities

Line

1. Post-processing grinding line for cylinder head/block

2. Post-processing grinding line for transmission

3. Cooling conveyor line for casting product

Exclusive

1. Knock out machine (Sand Core Knock-Out M/C)

2. Post-processing grinding line for transmission

3. Trimming Press

4. NC Endmill

5. NC Milling

6. Robot Deburring

7. Transfer unit (High Speed Gantry Loader)

8. Palletizing & Handing Robot

9. Chip & Sand Conveyor

10. Chip & Gate Separator

· Classification of facilities(Line Desc.)

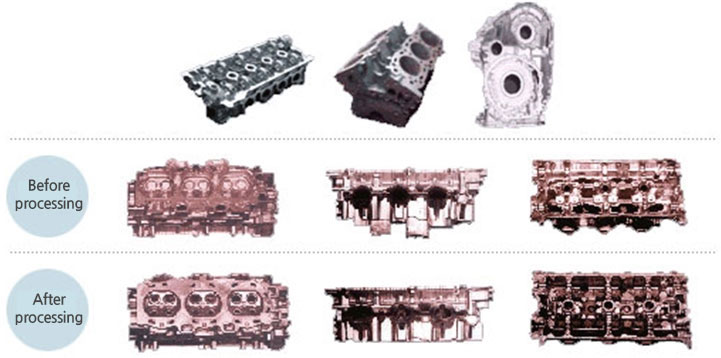

1. Grinding line for cylinder head/block

Composed of moving low pressure casting or gravity die casting work to transfer the unit for grinding → side milling → gate cutting → bottom surface trimming press → bottom surface NC endmill → upper surface trimming press → upper surface NC endmill → robot deburring → product loading robot → product loading pallet. Auxiliary facilities include chip conveyor & molding sand conveyor, chip and hole separation device, and dust collection device.

2. Grinding line for transmission

When the transfer robot moves the high pressure die casting work into the machine, a work clamp is applied on the jig. It is a compact system that aims to carry out post-processing in a small space by linking the 4-axis NC on the jig side and 3-axis NC on the tool side.

3. Cooling conveyor line for casting product

Temperature of aluminum material after casting is approx. 300˚C. Deformation might occur when grinding work is carried out on a high temperature material. To secure reliability and maximize production efficiency, this conveyor is used for cooling to 100˚C or below so that materials can be supplied to post processing facilities.

· Classification of facilities(single Desc.)

4. Independent device

By independently applying each process of the post-processing grinding line, installation can be set up anywhere as a compact type independent device.

- Knock out machine for molding sand

- Gate cutting machine for removing pouring gate on the casting

- Trimming press and NC milling for removing excessive burr

- NC endmil and robot deburring for removing fine burr

- Transfer unit for automatically returning material (High Speed Gantry Loader)

- Loading device for automatic loading of material (Palletizing & Handling Robot)

- Chip & Sand Conveyor

- Chip & Gate Separator

· Major target object