Environment Division

CONE TYPE Centrifuge

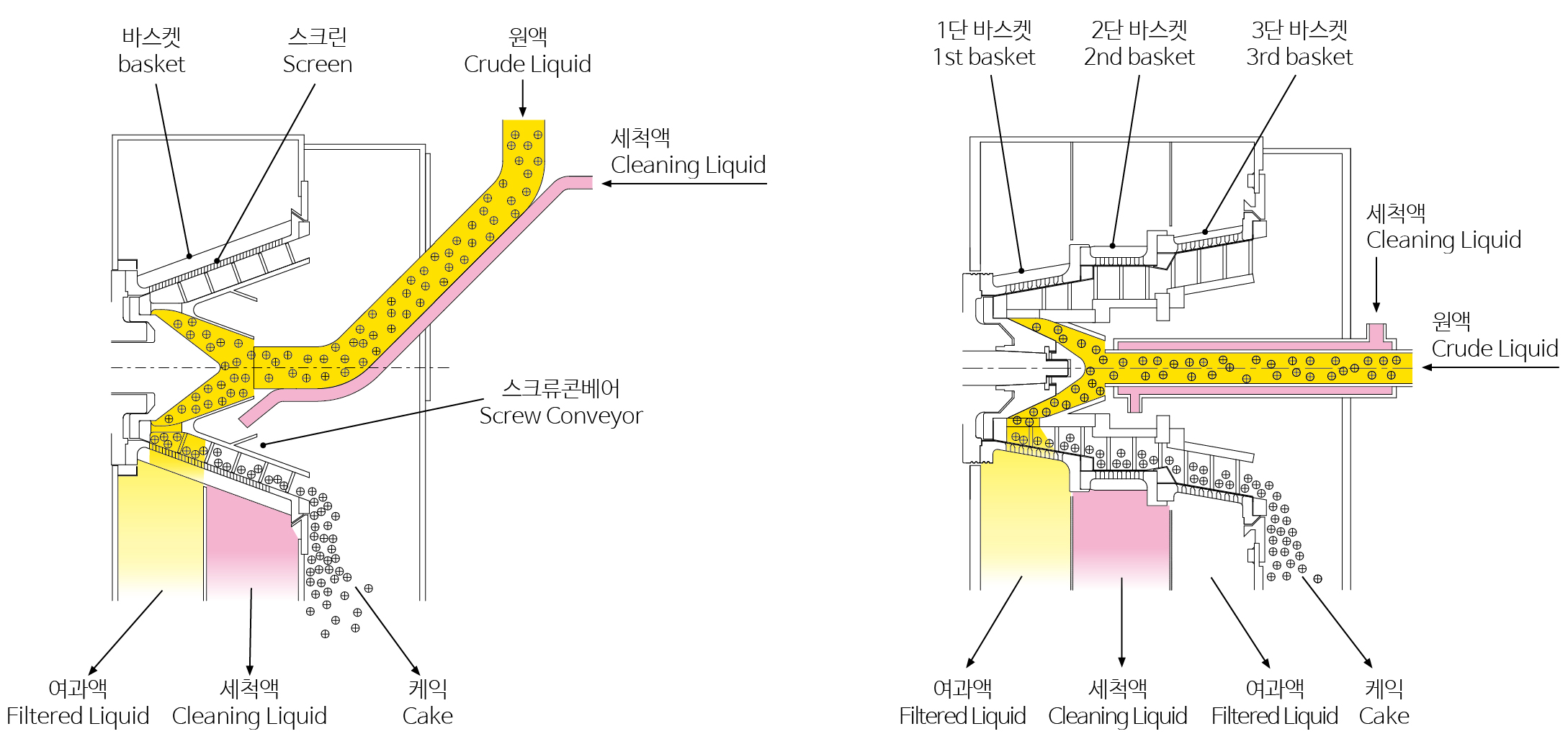

· BASKET TYPE

■ Standard basket type

■ Multiple basket type

· Continuous separation and cleaning of

particles with diameter 0.05mm-3mm

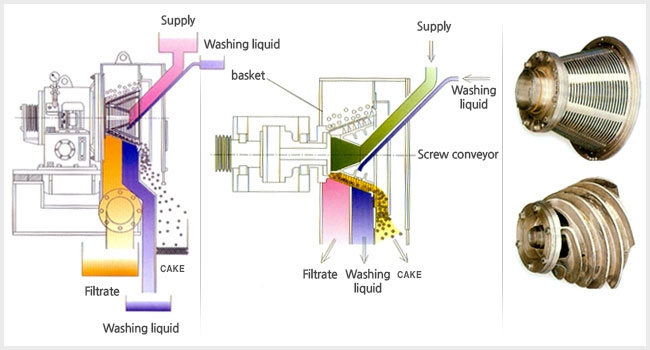

① The treated liquid is transferred to the screw conveyor revolving at high

speed.

② The accelerated revolving liquid passes through holes and into cone-type

basket.

③ The filtrate passes through screen to the discharge exit.

④ solids, blocked by screen, accumulate inside and then move to discharge by

the wings on screw conveyor.

⑤ When cleaning is necessary during the discharge process of solids,

detergents clean them, which are injected through the holes on screw

conveyor.

* Installed inside the basket, a special

screen is greatly improves the separation effect(dewatering).

* We are ready to serve and meet any client's

needs with various screens.

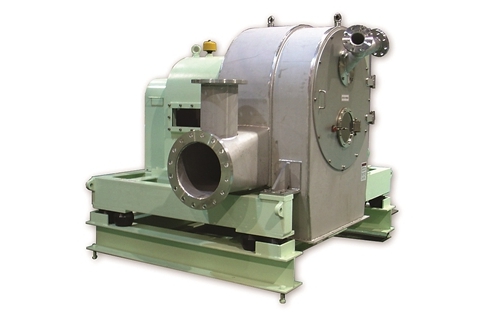

· Structure and Specification

With cone—typed basket combined with screw, the supply and separation of

crude liquid including cake discharge are simultaneously performed, which

is proper to a large volume job. contacting areas made of stainless steel

preserve all the time the machine's external appearance quite nice, and

employ vibrationproof structures to sustain even a continuous treatment of

large volume jobs without problems.

운전

Automatic continuous centrifugal separation is realized in full scale by

feeding crude liquid continuously.

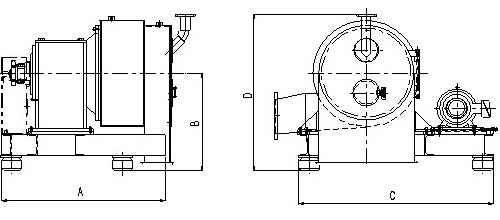

· Specifications and dimensions

| MODEL |

BASKET

Inner diameter(mm) |

Throughput

㎥/hr |

Rotation speed rpm

㎥/hr |

Centrifugal effect

G |

size mm |

MOTOR |

weight

kg |

| A |

B |

C |

D |

| FSC-300 |

300 |

2~5 |

3000 |

1500 |

890 |

555 |

1140 |

855 |

7.5Kw |

800 |

| FSC-400 |

400 |

5~10 |

2500 |

1400 |

950 |

870 |

1580 |

1070 |

18.5Kw |

1500 |

| FSC-550 |

550 |

10~25 |

2100 |

1250 |

1250 |

1130 |

2050 |

1405 |

30Kw |

2000 |

| FSC-700 |

700 |

25~50 |

1700 |

1100 |

1650 |

1530 |

2780 |

1710 |

55Kw |

2700 |