Environment Division

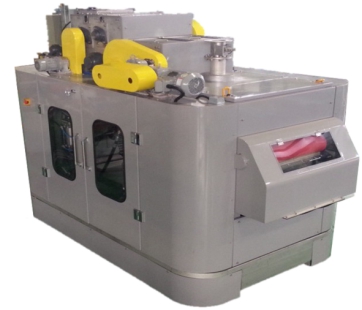

Electro-Osmosis Dehydrator

Unlike traditional mechanical type pressurized dehydration, the

Electro-osmosis type dehydration type uses Electrophoresis and

Electro-osmosis to separate moisture from sludge and achieve

high-efficiency dehydration.

When the sludge cake (moisture content of 80wt.% or above) that has gone

through 1st dehydration is supplied between the positive charged drum and

negative charged caterpillar. Since solid sludge particles are mostly

charged of (-) electric charge, By applying direct voltage, particles

moves to anode, and electro-osmosis pushes combined moisture in the sludge

to caterpillar for dehydration to achieve high-efficiency dehydration with

a moisture content of 60 wt.% or below.

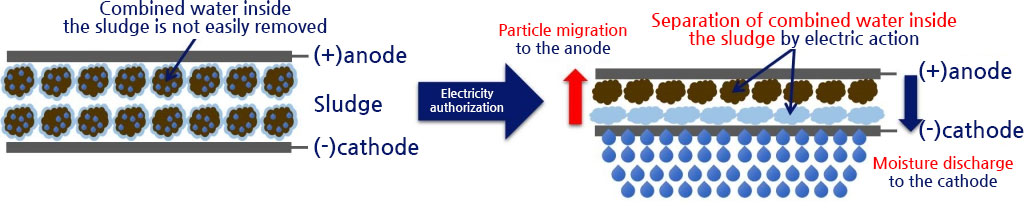

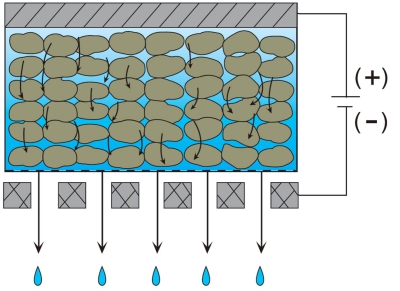

· Principle of electro-osmosis dehydration

technology

1. Electrophoresis: solid sludge particles (- charged) move to (+ charged)

anode.

2. Electro-osmosis: As the particles move to anode, moisture is discharged to

(- charged) cathode.

3. By applying electric field, polymers (flocculant) on sludge particle are

discharged due to destruction of bridge reaction.

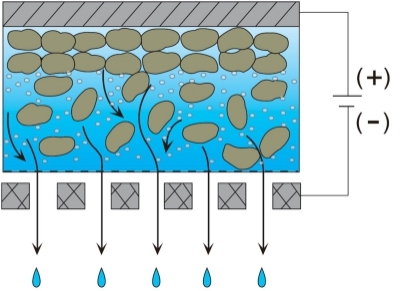

· Mechanism of electro-osmosis dehydration

technology

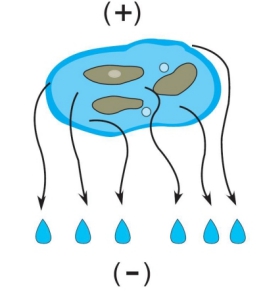

1. Initial stage:

Electrophoresis

Dry solids move to anode

2.Middle stage:

Electro-osmosis Separated

moisture moves to the cathode

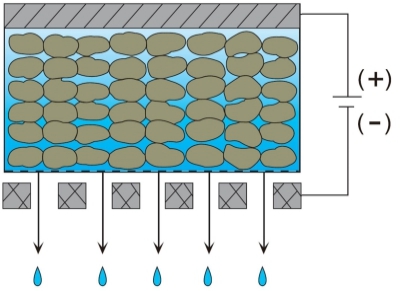

3. Main Stage:

Capillary force

Interstitial moisture combined with sludge dehydrated to the cathode

4. Final Stage:

Flocs Destruction by Electric field

Moisture in flocs is dehydrated through floc destruction