Environment Division

Other Centrifuge

Application

Oil and chip separation of machine tools.

Purification of machining oil and chip separation of machining equipments relate to semiconductor..

Elimination of mud, sand, and other solids during drainage process.

Structure

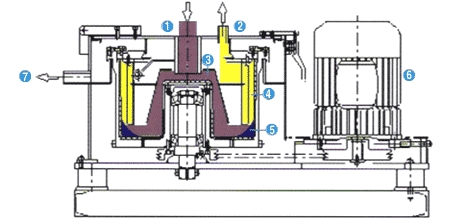

① = Inlet ② = Discharge Pipe ③ = Sludged Oil ④ = Cleaned Oil

⑤ = Solid Particles ⑥ = Motor ⑦ = Over Flow Pipe

| Application |

Optional Devices |

Pre treatment of polluted water disposal system

Collection of floating oil

Removal of floating impurities of the circulating cutting oil

Please attend to the oil that is impossibe to separate

|

The part which is solidified at nomal temperature

Clay material & oil ingredient of high specific gravity |

· Specifications

1. Clean machining oil enhances product quality and productivity as it extends the life expectancy of equipments and tools, dramatically reduces the products's defect rateand makes the holding time short for restart.

2. The equipment makes the post-process of sludge very simple, as it solidifies to separates small particles like large amount of abrasives, glasses, carbon, aluminum, stainless steels, and ceramics that are not easily removable by magnetic separators and other filters.

3. There can be seen no defects from scratches during grinding.

4. Unlike paper filter, filter press or other filters, consumables are not required.

5. Properties of special oil do not change, there is a little waste of liquid oil and prevent aging from heat.

6. No extra feeding pumps are necessary when draining the fluid.

7. The separator lowers temperature of water-soluble liquid and prevents decay.

· Format and Specification

| Model |

Capacity(ℓ/min) |

Inner volume( ℓ ) |

rpm |

Motor(Kw) |

Dimensions (mm) |

Weight(kg) |

| FIC-250 |

20∼60 |

3 |

2500 |

1.5 |

400×650×500 |

100 |

| FIC-400 |

75~150 |

12 |

2000 |

3.7 |

650×1000×600 |

650×1000×600 |

· Capacity

| Type / Flux(ℓ/min) |

5 |

10 |

20 |

30 |

50 |

75 |

100 |

150 |

| FIC-250 |

2 |

3 |

5 |

7 |

10 |

15 |

- |

- |

| FIC-400 |

1 |

1 |

2 |

3 |

5 |

7 |

10 |

30 |